Business inventories and sales serve as the backbone of modern commerce, weaving a dynamic relationship that dictates the rhythm and success of every enterprise. From bustling retail stores to intricate manufacturing lines, understanding how inventory and sales data interact can transform daily operations into a strategic advantage that sets thriving businesses apart from their competitors.

The topic of business inventories and sales covers the essentials of tracking goods, the types of inventory companies manage, and the various methods used to ensure products are available when needed. Technology has redefined how businesses monitor sales and inventory, making real-time reporting and automation more accessible and accurate than ever. By diving into real-world examples, management techniques, and digital tools, businesses can learn how to align inventory with sales strategy, overcome common challenges, and drive sustainable growth.

Business Inventories and Sales: Definition, Types, and Impact

Business inventories and sales are two fundamental pillars in the world of commerce. They serve as the backbone for operational efficiency, financial planning, and strategic growth. Understanding what they represent and how they interact is crucial for any business aiming to thrive in a competitive marketplace.

Definition and Importance of Business Inventories and Sales

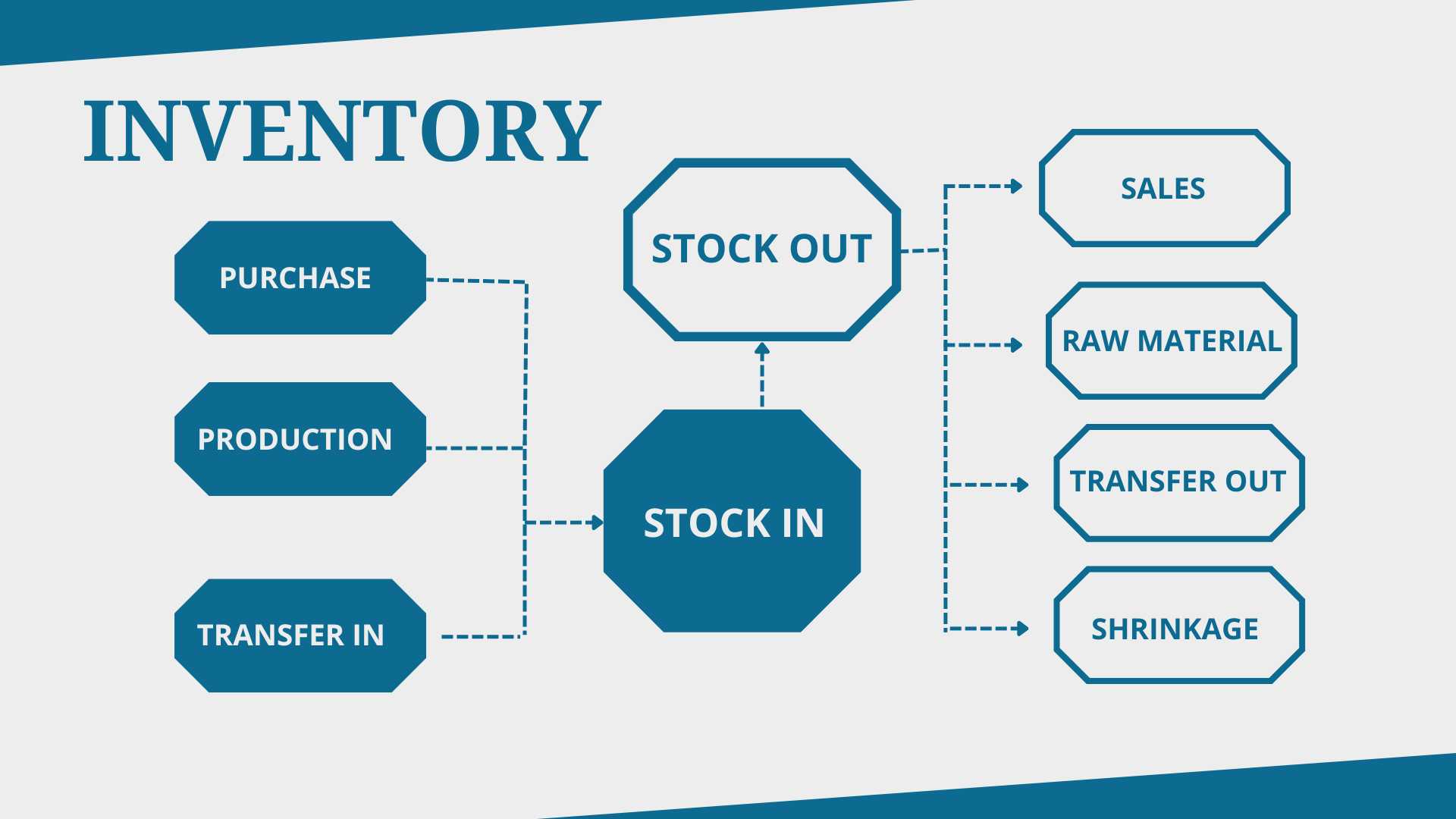

Business inventories refer to the goods and materials that a company holds for the purpose of resale, production, or maintenance. Sales, on the other hand, represent the transaction of these goods or services to customers, generating revenue for the business. Tracking both inventories and sales is vital for maintaining the balance between supply and demand, reducing costs, and identifying new opportunities for business improvement.

Efficient inventory and sales management enable businesses to optimize their working capital, avoid stockouts or overstocking, and respond quickly to market trends. Real-time data on inventory and sales allows companies to make informed decisions, streamline operations, and boost profitability.

| Industry | Inventory Type | Impact on Sales | Outcome |

|---|---|---|---|

| Retail (Apparel) | Seasonal Finished Goods | Proper tracking helps prevent excess stock and markdowns | Higher margins and rapid response to trends |

| Manufacturing (Electronics) | Raw Materials & Work-in-Progress | Efficient inventory ensures uninterrupted production and timely delivery | Greater customer satisfaction and repeat business |

| Wholesale (Food Distribution) | Perishable Goods | Accurate inventory data reduces spoilage and loss | Lower wastage, improved profitability |

| Automotive Services | MRO Supplies | Availability of parts affects service speed and customer trust | Enhanced operational efficiency and loyalty |

Types of Business Inventories

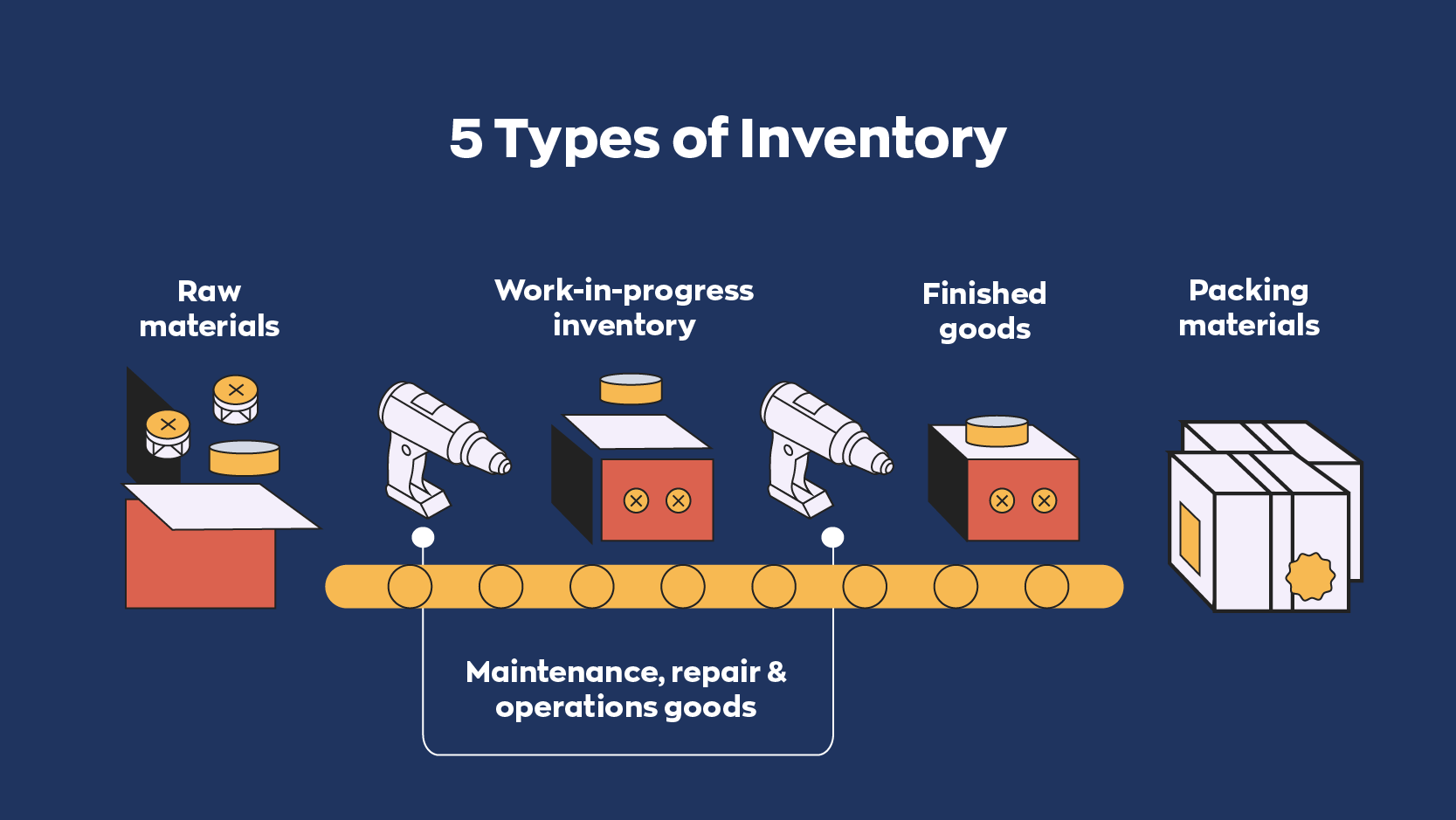

Inventories are categorized based on their role in the production and sales process. Understanding each type is essential for effective inventory management, especially as businesses diversify their operations and product lines.

Main Inventory Types and Their Characteristics

The four primary inventory types are raw materials, work-in-progress (WIP), finished goods, and MRO (Maintenance, Repair, and Operations) supplies. Each type presents unique management challenges and is used differently across various industries.

| Inventory Type | Description | Typical Industry Use | Management Challenges |

|---|---|---|---|

| Raw Materials | Basic inputs used to manufacture products | Manufacturing, Food Processing | Price fluctuations, perishability, supplier reliability |

| Work-in-Progress (WIP) | Items in the production process, not yet finished | Automotive, Electronics, Furniture | Tracking progress, cost allocation, bottlenecks |

| Finished Goods | Completed products ready for sale | Retail, Wholesale, Consumer Goods | Stockouts, obsolescence, inventory holding costs |

| MRO Supplies | Items for maintenance and repair of operations | Manufacturing, Healthcare, Service industries | Usage unpredictability, excess storage, expiration |

Industry-specific examples demonstrate how businesses utilize different inventory types:

- Food Processing: Raw materials like grains, spices, and packaging supplies must be closely monitored to avoid spoilage and ensure food safety.

- Furniture Manufacturing: Work-in-progress inventories include partially assembled items and components, requiring regular tracking to identify production delays.

- Consumer Electronics Retail: Finished goods such as smartphones and accessories must be rotated quickly to prevent obsolescence as new models are released.

- Automotive Repair Shops: MRO supplies like lubricants, filters, and spare parts are vital for day-to-day service delivery, demanding efficient stock management.

Inventory Management Methods: Business Inventories And Sales

Selecting the right inventory management method is crucial for balancing cost, efficiency, and customer satisfaction. Different methods suit different business models and industries, each with distinct procedures and outcomes.

Comparison of Inventory Management Methods

The most widely adopted inventory management methods are FIFO (First-In, First-Out), LIFO (Last-In, First-Out), JIT (Just-In-Time), and EOQ (Economic Order Quantity). Each method impacts inventory valuation, cash flow, and responsiveness to market changes.

| Method | Key Features | Advantages | Limitations |

|---|---|---|---|

| FIFO | Oldest inventory is sold first; aligns with actual flow for perishables | Reduces risk of obsolescence, matches physical flow, ideal for food/medicine | May inflate profits during inflationary periods |

| LIFO | Newest inventory is sold first; used for non-perishable items | Matches recent costs with revenue, can lower taxable income in inflation | Can result in outdated stock, banned in some countries under IFRS |

| JIT | Inventory ordered only as needed for production/sale | Minimizes holding costs, reduces waste, increases efficiency | Vulnerable to supply chain disruptions, requires precise forecasting |

| EOQ | Calculates optimal order quantity to minimize total costs | Balances ordering and holding costs, improves cash flow | Requires accurate demand and cost data, less flexible for demand spikes |

The chosen inventory management method can significantly influence sales performance. For instance, JIT allows companies to react quickly to customer orders and trends, reducing excess inventory but increasing reliance on supplier reliability. Meanwhile, FIFO ensures fresh stock is always available, which is crucial for industries with expiration-sensitive products. The right method helps prevent stockouts, reduces costs, and enhances customer satisfaction, all of which directly impact sales success.

Impact of Inventory Management Methods on Sales Performance, Business inventories and sales

A proactive approach to inventory management ensures that popular products are always available, seasonal trends are addressed, and slow-moving items are identified early. This leads to increased sales, fewer missed opportunities, and enhanced brand reputation. Efficient management methods also allow for better promotional planning and inventory turnover, fueling business growth over time.

Last Word

Mastering business inventories and sales is a cornerstone for achieving efficiency, customer satisfaction, and long-term profitability. As technology continues to evolve and businesses adopt smarter management solutions, those who effectively connect inventory insights to sales strategies will remain nimble and well-positioned for growth in any market landscape. Take inspiration from successful case studies and consider how your own processes can benefit from the best practices highlighted throughout this discussion.

FAQ Overview

What is the difference between inventory and sales?

Inventory refers to the products or materials a business has on hand, while sales represent the transactions where these products are sold to customers.

How can poor inventory management affect sales?

Poor inventory management can result in stockouts, causing missed sales opportunities, or overstock, leading to unnecessary storage costs and potential product obsolescence.

What tools can small businesses use to manage inventories and sales?

Small businesses often use point-of-sale (POS) systems, inventory management software, and spreadsheets to track inventories and monitor sales performance.

Why is sales forecasting important for inventory management?

Sales forecasting helps predict future demand, allowing businesses to optimize inventory levels, reduce excess stock, and avoid running out of products during high demand periods.

Can automation help prevent human error in inventory and sales management?

Yes, automation reduces manual entry and streamlines processes, minimizing human error and providing more accurate data for decision-making.