business inventories forms the backbone of modern commerce, serving as the silent powerhouse that drives efficiency, profitability, and seamless operations in every industry. From bustling manufacturing plants to vibrant retail stores, understanding how inventories are managed can make the difference between thriving and merely surviving in today’s competitive landscape.

At its core, business inventories encompass raw materials, work-in-progress, and finished goods—each playing a vital role in the production and supply chain. Effective inventory management not only keeps business operations running smoothly but also safeguards against costly pitfalls like overstocking or stockouts. It’s about finding the sweet spot where supply meets demand, using a blend of time-tested methods and cutting-edge technology to streamline processes, boost financial performance, and enhance decision-making across the board.

Introduction to Business Inventories

Business inventories are an essential component in the supply chain of any organization, regardless of industry. They represent the goods and materials a business holds for the purpose of resale, production, or operational use. Effective inventory management ensures that a company can meet customer demand without incurring unnecessary costs or risking stockouts.

Inventories serve multiple purposes, from supporting day-to-day operations to acting as a buffer against supply chain fluctuations. Businesses across sectors—manufacturing, retail, distribution, and even service industries—rely on careful inventory planning to maintain operational efficiency and optimize resources.

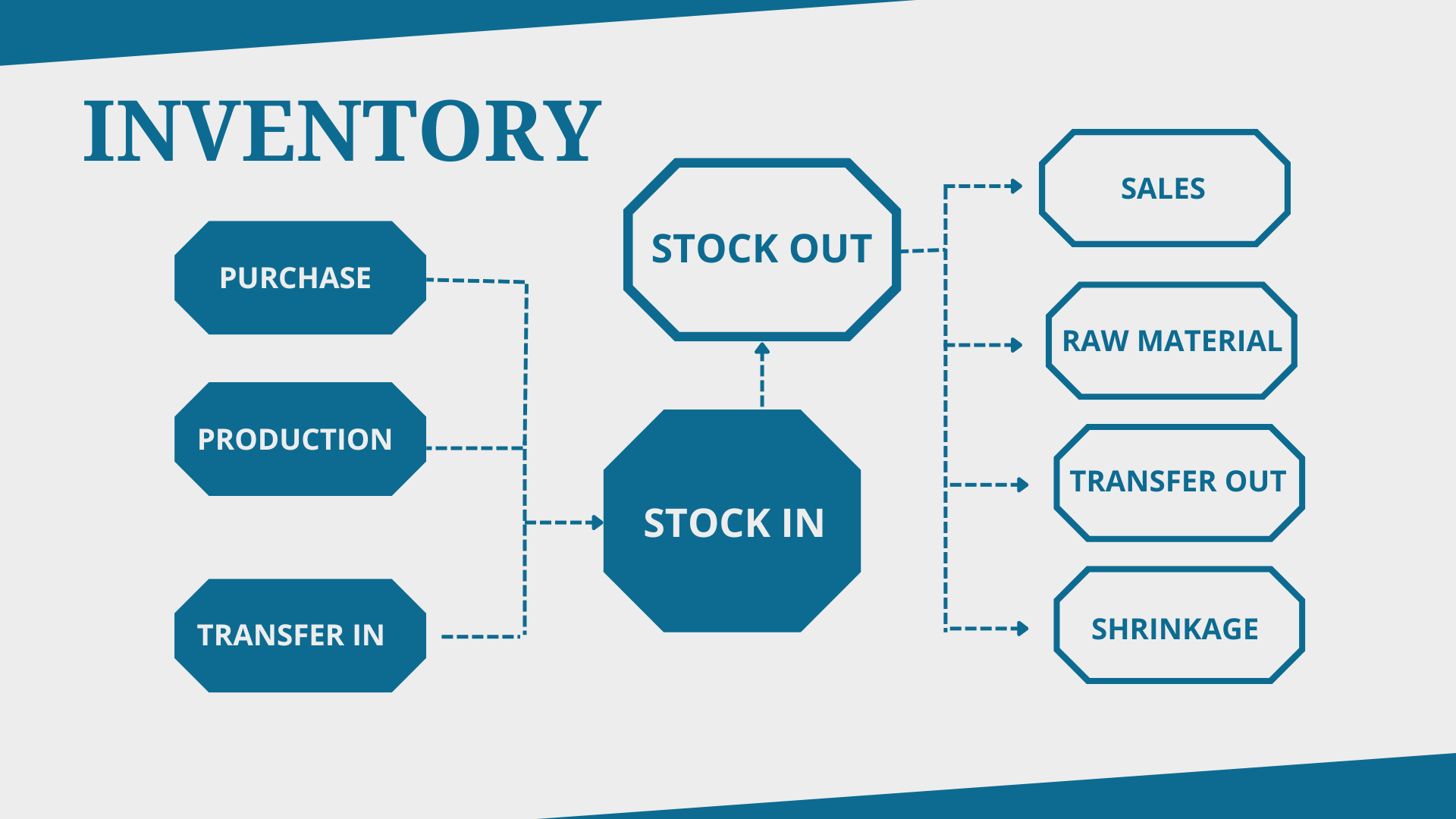

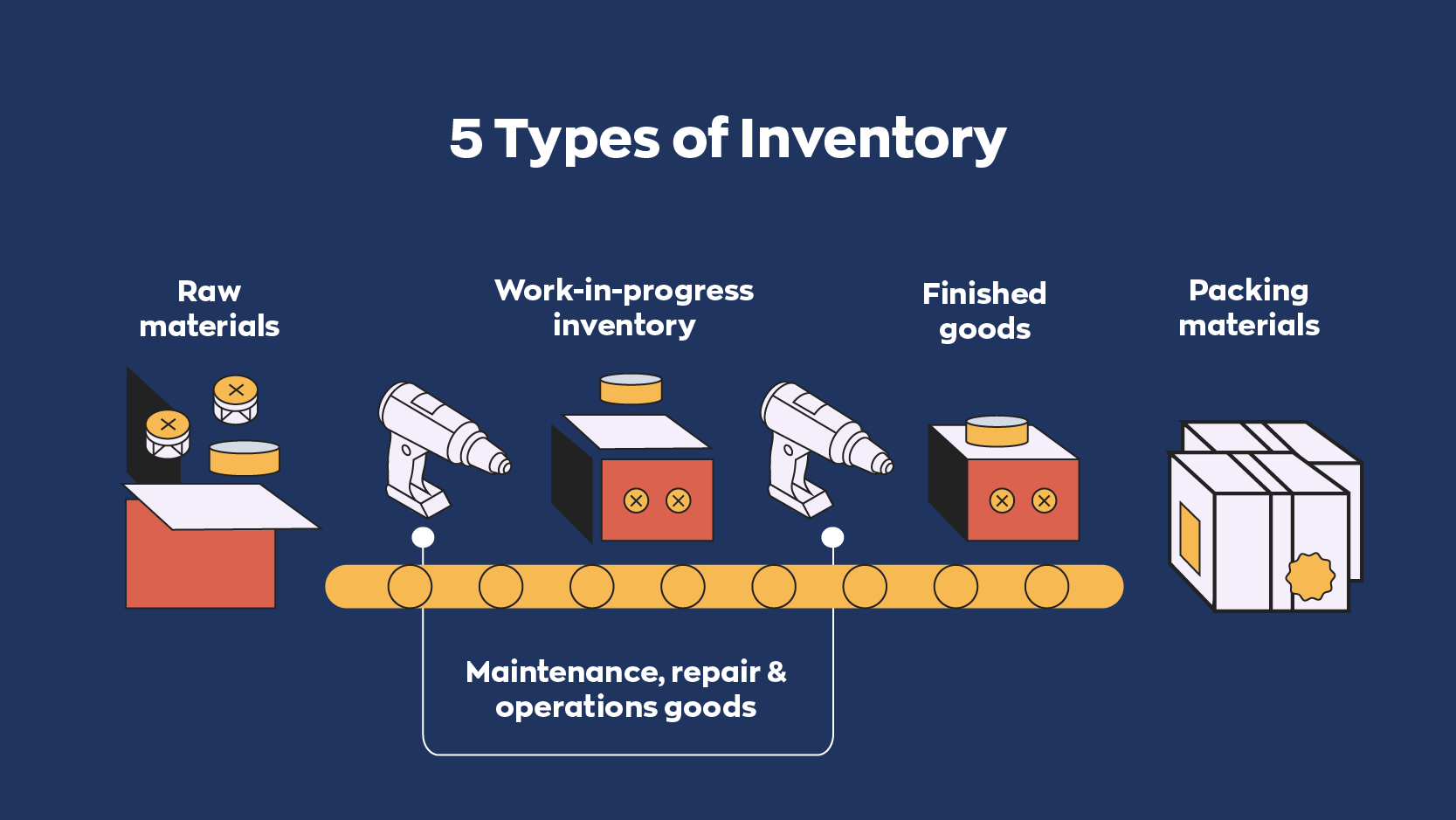

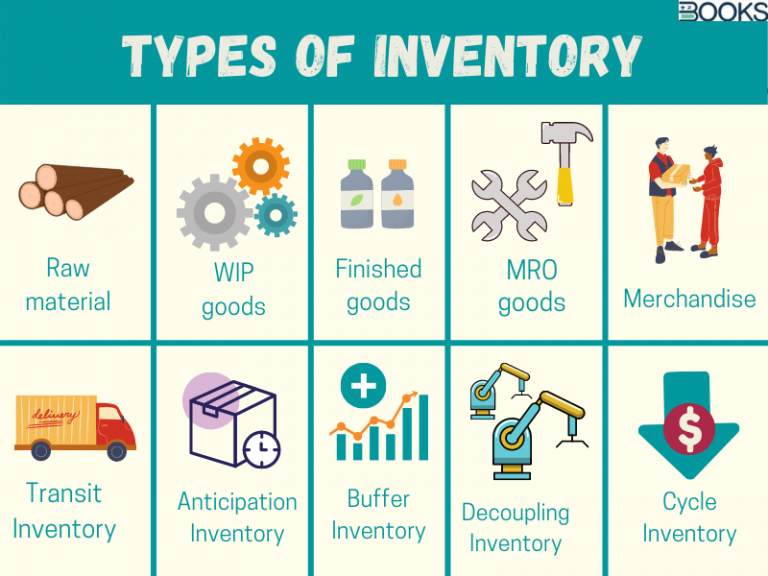

Types of Business Inventories

Understanding the different categories of business inventories is crucial for managing them efficiently. The main types include raw materials, work-in-progress (WIP), and finished goods. Each type plays a distinct role in the production and sales processes.

- Raw Materials: Basic inputs purchased from suppliers to be used in the manufacturing process.

- Work-in-Progress (WIP): Items that are in the middle of the production process but are not yet finished products.

- Finished Goods: Products that have completed the manufacturing process and are ready for sale or distribution.

Inventory Management and Business Operations, Business inventories

The relationship between inventory management and business operations is deeply interconnected. Well-managed inventories enable smooth production schedules, reduce carrying costs, increase cash flow, and improve customer satisfaction. Conversely, poor inventory handling can disrupt production, cause delays, and lead to missed sales opportunities.

Importance of Effective Inventory Management

Proper inventory management is vital for maximizing profitability and ensuring healthy cash flow. Companies that excel in inventory control can react swiftly to changes in demand, avoid tying up excessive capital in unsold goods, and reduce waste or spoilage.

Ineffective inventory practices often result in either overstocking or stockouts, each with its own negative consequences. By analyzing common scenarios, businesses can identify root causes and implement practical solutions.

Examples of Inventory Management Challenges

The following table provides real-world scenarios that highlight the impact of poor inventory management, along with suggested solutions.

| Scenario | Cause | Effect | Solution |

|---|---|---|---|

| Overstocking seasonal products | Inaccurate demand forecasting | Increased holding costs, possible markdowns | Implement advanced forecasting and regular inventory reviews |

| Frequent stockouts of popular items | Poor replenishment planning | Lost sales, dissatisfied customers | Adopt automated reorder points and safety stock policies |

| Obsolete inventory accumulation | Lack of product lifecycle management | Write-offs, wasted storage space | Establish clear product phase-out procedures and monitor trends |

| Excessive perishable goods waste | No FIFO system in place | Spoilage, decreased profit margins | Use FIFO method and frequent stock rotation |

Inventory Turnover and Decision Making

Inventory turnover measures how many times a company’s inventory is sold and replaced over a specific period. This ratio is a key indicator of inventory management efficiency and directly influences purchasing strategies, production planning, and financial performance.

- High inventory turnover typically signals strong sales and effective inventory management.

- Low inventory turnover may indicate overstocking, slow-moving goods, or declining market demand.

- Companies should analyze turnover data regularly to adjust purchasing, improve cash flow, and optimize stock levels.

Inventory Turnover Ratio = Cost of Goods Sold / Average Inventory

Methods and Systems for Managing Business Inventories

Selecting the right inventory management method can significantly affect a business’s efficiency, costs, and ability to meet customer demand. Companies may use different approaches based on their industry, product type, and operational goals.

Inventory Management Methods

The most common inventory management methods include First-In, First-Out (FIFO); Last-In, First-Out (LIFO); and Just-In-Time (JIT). Each method offers unique benefits and challenges, as summarized in the table below.

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| FIFO | Oldest inventory items are sold or used first | Reduces risk of obsolescence, aligns with physical flow of goods | May increase taxes during inflationary periods |

| LIFO | Newest inventory items are sold or used first | Tax advantages during inflation, matches recent costs with revenues | Inventory may become outdated, not permitted under IFRS |

| Just-In-Time (JIT) | Inventory is received only as needed for production or sales | Minimizes holding costs, reduces waste | Requires reliable suppliers, vulnerable to disruptions |

Manual Versus Automated Inventory Systems

Businesses can choose between traditional manual inventory tracking methods and modern automated systems. Understanding the features of each approach helps organizations select the best fit for their needs.

- Manual Systems: Relies on spreadsheets, paper logs, and physical stock counts. Suitable for small businesses with limited inventory.

- Automated Systems: Uses specialized software, barcode scanners, and real-time data updates. Allows integration with sales, purchasing, and accounting platforms.

- Automated systems provide increased accuracy, efficiency, and scalability, while manual systems may be prone to human error and time-consuming processes.

Procedures for Conducting Regular Inventory Audits

Routine inventory audits help ensure records match actual stock levels and identify discrepancies early. A systematic approach includes:

- Scheduling periodic physical counts (monthly, quarterly, or annually).

- Reconciling physical counts with system records.

- Investigating and correcting variances promptly.

- Reviewing audit findings to improve inventory processes and prevent recurring issues.

Final Summary: Business Inventories

As we wrap up our exploration of business inventories, it’s clear that mastering inventory management is essential for sustainable business growth and resilience. Whether you’re leveraging advanced technologies, refining your audit processes, or staying ahead of future trends, a strategic approach to inventories empowers your business to adapt, optimize, and succeed in a rapidly evolving marketplace.

Question Bank

What are the main types of business inventories?

The main types include raw materials, work-in-progress, and finished goods, each representing different stages of the production cycle.

How often should businesses conduct inventory audits?

Businesses should conduct inventory audits at least once a year, but quarterly or even monthly audits are recommended for better accuracy and control.

Can small businesses benefit from automated inventory systems?

Yes, automated inventory systems help small businesses reduce errors, save time, and improve overall efficiency, making them a valuable investment.

What is inventory shrinkage and how can it be prevented?

Inventory shrinkage refers to the loss of stock due to theft, damage, or errors. Prevention strategies include regular audits, employee training, and security measures.

How does inventory management impact customer satisfaction?

Effective inventory management ensures products are available when customers need them, reducing delays and boosting satisfaction and loyalty.